Wet and gel spinning technology

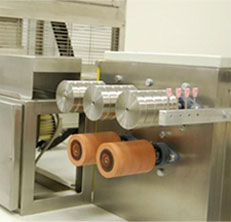

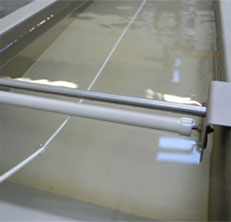

For those projects where melt spinning solutions cannot succeed, FET designs and manufactures Laboratory and Pilot Wet and Gel Spinning Systems. This process is used for polymers that need to be dissolved in a solvent to be spun.

In the case of wet spinning, the spinneret is submerged in a chemical bath that causes the fibre to precipitate, and then solidify, as it emerges. Gel spinning is sometimes described as dry-wet spinning, since the filaments first pass through air and then are cooled further in a liquid bath.

Solvent spinning is used to obtain high strength or other special properties in the fibres. The polymer is in a “gel” state, which keeps the polymer chains somewhat bound together. These bonds produce strong inter-chain forces in the fibre, which increase its tensile strength. The polymer chains within the fibres also have a large degree of orientation, which increases strength. Some high strength polyethylene fibres are produced via this process.

For more details about Wet and Gel spinning technology, please contact FET for advice.